Boiler Fault codes

Common boiler issues you can remedy

One of the most commonly searched problems is boiler pressure. so what can you do to fix this issue?

What Should the Pressure Be?

Most boilers operate best when the pressure gauge reads between 1.0 and 1.5 bar when the system is cold. When your heating is on, the pressure may rise slightly, typically sitting between 1.5 and 2.0 bar.

If the pressure falls below 1.0 bar, it’s considered low and may require topping up.

How to Check and Top Up Your Boiler Pressure

Low boiler pressure is one of the most common issues homeowners face — and it can stop your central heating or hot water from working efficiently. Thankfully, checking and topping up your boiler pressure is a simple task you can do yourself, as long as you follow the steps carefully.

How to Check Your Boiler Pressure

Locate the pressure gauge

This is usually found on the front of your boiler’s control panel. It will either be a physical dial or a digital reading.Read the current pressure

The dial will likely be colour-coded:Green zone: Normal

Red zone (low): Pressure too low

Red zone (high): Pressure too high

How to Top Up Boiler Pressure

Before beginning, it’s important to turn off your boiler and allow it to cool down completely. Most systems will use one of the two following filling methods:

Method 1: External Filling Loop

Locate the filling loop

This is a silver, braided flexible hose underneath your boiler, connecting the central heating and mains cold water pipes.Turn both valves

Slowly open both ends of the filling loop. You should hear water begin to flow.Watch the pressure gauge

When the needle reaches 1.5 bar, close both valves immediately.Restart your boiler

Once pressure is correct and valves are closed, you can turn your boiler back on.

Method 2: Internal Filling Key (e.g., Worcester Bosch Boilers)

Insert the key

Slot the plastic key into the filling point underneath the boiler and turn to lock it in place.Turn the filling knob

Gently turn the knob to begin water flow. Monitor the pressure gauge carefully.Stop at 1.5 bar

Once the correct pressure is reached, turn the knob back to the off position and remove the key.

Important Notes

Only top up the pressure when your system is cool.

Do not overfill. A pressure above 2.5 bar could lead to system damage or leaks.

If your pressure drops frequently, this could indicate a leak or fault in the expansion vessel. In that case, contact a Gas Safe engineer.

Still Having Issues?

JJK Gas Services offers professional, fast-response boiler servicing and repairs throughout Wigan and the surrounding areas.

We can identify pressure issues, repair faults, and ensure your boiler runs safely and efficiently.

Contact Us:

Phone: 01942 466 486

Booking: Contact JJK Gas Services: Wigan Gas Engineer – Call Today

No heating or hot water.

No Heating or Hot Water? Simple Checks Before You Call a Boiler Engineer in Wigan

One of the most common boiler issues searched by homeowners in the UK is: “Why do I have no heating or hot water?” This can be frustrating, especially in colder months. At JJK Gas Services, our Gas Safe registered engineers in Wigan are often called out to deal with this exact issue — but before you book a callout, here are a few safe steps you can take yourself.

These tips apply to combi boilers, system boilers, and regular boilers across homes in Wigan, Leigh, Tyldesley, Atherton, and surrounding areas.

1. Check Your Thermostat Is Set Correctly

Make sure your thermostat:

Has working batteries (if wireless)

Is turned up above the current room temperature

Is set to “heating” or “hot water” mode

Old thermostats or recent power cuts can reset your heating schedule, causing boiler downtime.

2. Review Your Heating Timer or Programmer

Whether digital or mechanical, ensure:

The time and date are correct

Heating and hot water schedules are set properly

The system isn’t accidentally set to “off” or “holiday” mode

Incorrect programming is a common reason for boiler faults in Wigan homes.

3. Check the Boiler Display for Error Codes

If your boiler has an LCD screen or status lights, note any fault codes or flashing indicators. Common error messages like F22 (Vaillant) or E119 (Ideal) often relate to low pressure or system faults.

Take a photo of the display — it can help us diagnose faster when we arrive.

4. Ensure the Boiler Has Power

Basic but vital:

Check the fused spur switch is turned on

Look for any tripped switches on your fuse board

Has the boiler been turned off by accident?

Power interruptions are a top cause of boiler shutdowns — especially during stormy weather.

5. Check Your Boiler’s Water Pressure (View Only)

Low pressure is one of the most searched combi boiler faults in the UK.

Look at the pressure gauge (should be between 1.0 and 1.5 bar)

If it’s below 1.0 bar, the system may need topping up

Only top up the pressure if you feel confident — otherwise, call a professional

Don’t attempt this if you’re unsure — contact a Gas Safe engineer in Wigan.

6. Radiators Cold at the Top? Bleed Them

Cold radiators could indicate trapped air in the system. Bleeding the radiators can restore proper heating, but be aware this can also lower boiler pressure — so again, proceed with caution.

Still No Heating or Hot Water?

If you’ve checked all of the above and the problem persists, your system likely needs expert attention. Common boiler issues we fix include:

Faulty diverter valves (hot water not prioritised)

Broken thermostats or sensors

Airlocks in the system

Low water pressure

PCB and pump faults

Book a Local Gas Safe Engineer in Wigan

At JJK Gas Services, we provide fast-response boiler repair, boiler servicing, and emergency plumbing across Wigan and Greater Manchester. We’re trusted by landlords, homeowners, and businesses for honest advice and top-rated heating services.

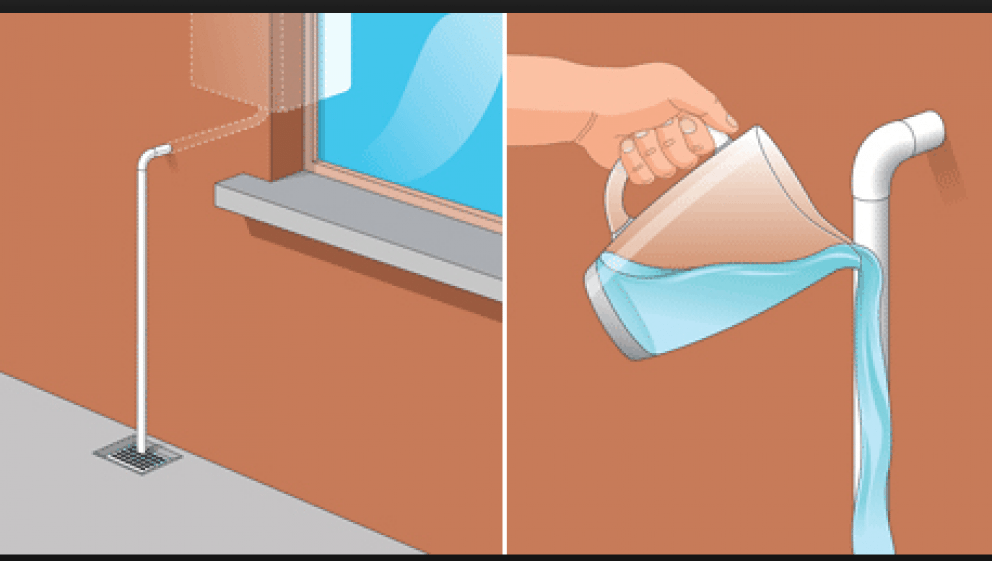

Frozen Condensate Pipe – Common Winter Boiler Issue

What Is a Frozen Condensate Pipe?

During freezing weather, the external condensate pipe connected to your boiler can freeze, causing blockages and forcing the boiler to shut down for safety. This is one of the most searched winter boiler faults in the UK and often affects combi boilers with external pipework.

Signs Your Condensate Pipe Is Frozen

If your boiler stops working suddenly during cold weather and displays a fault code (like F1, F28, or EA), it could indicate a frozen pipe. You might also hear gurgling sounds or see water dripping from a joint in the pipe.

How to Fix It Yourself Safely

If safe to do so, pour warm (not boiling) water over the external pipe to thaw the blockage. Start at the top and work your way down. You can also apply a warm cloth or hot water bottle to help melt the ice.

Preventing Future Freezing

Insulating the condensate pipe with foam pipe lagging is a simple and effective way to prevent future freezes. A boiler engineer can also reroute or upgrade the pipework for improved protection.

Need Professional Help?

If you’re still having issues, contact JJK Gas Services, your trusted local boiler specialists in Wigan. We provide fast, reliable repairs and winter-ready boiler servicing. Call: 01942 466 486 if your still having problems.

Boiler Fault Code Encyclopedia

The complete database of 120+ error codes. Trusted by Wigan's leading engineers.

Worcester Bosch

| Code | Type | Meaning | How to Fix / Action |

|---|---|---|---|

| EA / 227 | Check | Ignition Fail | No flame detected. Check gas meter. Check condensate pipe for ice. |

| A1 / 229 | DIY Fix | Low Pressure | System water low. Top up via filling key/loop to 1.5 bar. |

| E9 / 224 | Engineer | Safety Lockout | Overheating in heat exchanger. Pump failure or thermostat issue. |

| C6 / 215 | Engineer | Fan Fault | Fan speed inconsistent. Blocked flue or fan failure. |

| D1 / 240 | Engineer | Return Sensor | Return NTC sensor damaged or wet. |

| E2 / 222 | Engineer | Flow Sensor | Flow NTC short circuit to ground. |

| E5 / 219 | Engineer | Return Sensor | Return NTC sensor fault (open circuit). |

| C0 / 200 | Engineer | Fan Speed | Fan running too high. Check mains voltage. |

| C2 / 204 | Engineer | Fan Error | Fan not spinning during startup. Motor seized. |

| A7 / 360 | Engineer | Hot Water NTC | DHW sensor defect. Incorrect hot water temp reading. |

| A8 / 362 | Engineer | BUS Comms | Communication error with thermostat/timer. |

| B7 / 257 | Engineer | Internal Error | Control board memory error. PCB replacement likely. |

| CE / 207 | DIY Fix | Low Pressure | System pressure very low. Top up immediately. |

| F0 / 238 | Engineer | Internal Error | Gas valve check failed. PCB or Gas Valve fault. |

| H7 / 328 | DIY Fix | Low Pressure | Water pressure low (Dry Boiler). Refill system. |

Baxi / Potterton

| Code | Type | Meaning | How to Fix / Action |

|---|---|---|---|

| E119 | DIY Fix | Low Pressure | Most common. Top up pressure to 1.5 bar. |

| E133 | Check | Gas Failure | Ignition failed. Frozen condensate or gas off. |

| E168 | Engineer | PCB Fault | "Ghost Fault". Power issue or PCB memory error. |

| E110 | Engineer | Overheat | Primary circuit overheated. Pump seized or airlock. |

| E160 | Engineer | Fan Fault | Fan speed threshold not reached. |

| E125 | Engineer | Circulation | Water not moving. Pump failure or air in system. |

| E118 | DIY Fix | Low Pressure | Gauge is too low. Top up system. |

| E109 | Engineer | Pre-Check Fail | System has air or pump is stuck. |

| E20 | Engineer | NTC Fault | Central heating thermistor faulty. |

| E28 | Engineer | Flue Sensor | Flue gas sensor fault. |

| E154 | Engineer | Flow Check | Hardware detection fault. Control board issue. |

| E78 | Engineer | Gas Valve | Gas valve control unit not recognised. |

| E50 | Engineer | DHW Sensor | Hot water sensor short circuit. |

| E117 | DIY Fix | High Pressure | System over 2.5 bar. Bleed a radiator to lower it. |

| E193 | Engineer | Air Lock | Circulation poor. Air trapped in heat exchanger. |

Ideal Logic / Vogue

| Code | Type | Meaning | How to Fix / Action |

|---|---|---|---|

| F1 | DIY Fix | Low Pressure | Pressure low. Use filling loop to top up. |

| L2 | Check | Ignition Lock | Flame loss. Check condensate/Gas. Reset. |

| F2 | Engineer | Flame Loss | Flame lit then went out. Flue/Gas Valve. |

| F3 | Engineer | Fan Fault | Fan failed to run. |

| FD | Engineer | No Water Flow | Boiler running dry. Pump seized. |

| F4 | Engineer | Flow Thermistor | Flow NTC sensor fault. |

| F5 | Engineer | Return Thermistor | Return NTC sensor fault. |

| F6 | Engineer | Outside Sensor | External sensor battery dead or wiring cut. |

| F9 | Engineer | PCB Fault | PCB unconfigured. Needs reprogramming. |

| L1 | Engineer | Flow Temp High | Flow temp too high. Poor circulation. |

| LC | Check | Ignition | 5 failed ignition attempts. Reset boiler. |

| FU | Engineer | Diff Temp | Flow/Return temp difference >50C. Pump fail. |

| L9 | Engineer | Heat Exchanger | Heat exchanger overheat. Blockage suspected. |

| L5 | Engineer | Return High | Return temp higher than flow. Sensor error. |

| FE | Engineer | PCB ID | Incorrect personality plug inserted. |

Vaillant ecoTEC

| Code | Type | Meaning | How to Fix / Action |

|---|---|---|---|

| F.22 | DIY Fix | Low Water | Top up pressure using filling loops. |

| F.28 | Check | Ignition Fail | No gas or frozen condensate pipe. |

| F.75 | Engineer | Pump/Sensor | Pressure sensor clogged with sludge. |

| F.29 | Engineer | Pilot Out | Flame lost during operation. Flue/Gas. |

| F.61 | Engineer | Gas Valve | Gas valve control logic error (PCB). |

| F.24 | Engineer | Low Water | Pump running dry. Temp rising too fast. |

| F.62 | Engineer | Gas Valve | Gas valve leaking or delay in closing. |

| F.72 | Engineer | NTC Fault | Flow/Return sensors drifted. |

| F.10 | Engineer | Flow Short | Flow sensor short circuit. |

| F.20 | Engineer | Overheat | Safety limiter tripped. Pump failure. |

| F.32 | Engineer | Fan Speed | Fan speed deviation. Blocked flue. |

| F.49 | Engineer | eBus | Low voltage on eBus. Wiring short. |

| F.63 | Engineer | PCB | EEPROM error. Main board failure. |

| F.64 | Engineer | Electronics | Short circuit in sensor wiring. |

| F.67 | Engineer | Flame Signal | Flame detected before ignition. Electrode fault. |

Viessmann

| Code | Type | Meaning | How to Fix / Action |

|---|---|---|---|

| F2 | Engineer | Overheat | Pump seized or airlock in system. |

| F4 | Check | Ignition | No flame signal. Check gas supply. |

| F5 | Engineer | Fan/Air | Air pressure switch stuck. |

| F30 | Engineer | Thermistor | Boiler water thermistor short circuit. |

| F50 | Engineer | Hardware | No internal hardware detected. |

| F51 | Engineer | DHW Sensor | Outlet temp sensor shorted. |

| F9 | Engineer | Fan Speed | Fan speed too low on start-up. |

| A0 | Engineer | Gas Valve | Gas valve control module fault. |

| F10 | Engineer | Outside NTC | Outside temp sensor short circuit. |

| F59 | Engineer | DHW Sensor | DHW sensor disconnected. |

| B7 | Engineer | Coding Plug | Coding card missing or faulty. |

| E4 | Engineer | Power | 24V supply voltage fault. |

| E6 | DIY Fix | Low Pressure | Water pressure too low. Top up. |

| EE | Engineer | Flame Signal | Flame signal weak. Clean electrodes. |

| F1 | Engineer | Flue Gas | Flue gas temperature limiter tripped. |

Glow-worm

| Code | Type | Meaning | How to Fix / Action |

|---|---|---|---|

| F1 | Check | Ignition | No gas or condensate blocked. |

| F22 | DIY Fix | Low Pressure | Water pressure low. Top up to 1.5 bar. |

| F75 | Engineer | Sensor/Pump | Pump running but no pressure rise. |

| F9 | Engineer | Circulation | Pump failure or blockage. |

| F4 | Check | Ignition | No flame detected. |

| F12 | Engineer | UI Fault | User Interface board connection lost. |

| F13 | Engineer | PCB | Main PCB memory error. |

| F25 | Engineer | Flue Temp | Flue temperature too high. |

| F28 | Check | Ignition | Failed to light after attempts. |

| F29 | Engineer | Pilot Out | Flame lost during heating. |

| F61 | Engineer | Gas Valve | Gas valve control fault. |

| F62 | Engineer | Gas Valve | Valve leaking or stuck open. |

| F72 | Engineer | NTC Fault | Flow/Return sensors inconsistent. |

| F83 | Engineer | Burner | Burner temp sensor fault. |

| F84 | Engineer | NTC Diff | Flow/Return temp difference invalid. |

Alpha Heating

| Code | Type | Meaning | How to Fix / Action |

|---|---|---|---|

| E10 | DIY Fix | Low Pressure | System needs topping up to 1-1.5 bar. |

| E01 | Check | Ignition | No flame lit. Check gas supply. |

| E02 | Engineer | Overheat | Thermostat tripped. Pump failure. |

| E03 | Engineer | Flue Block | Flue pressure switch fault. |

| E05 | Engineer | Flow Sensor | Flow thermistor faulty. |

| E06 | Engineer | DHW Sensor | Hot water sensor faulty. |

| E15 | Engineer | Return Sensor | Return thermistor faulty. |

| E20 | Engineer | Safety | Flame control safety lock. |

| E40 | Engineer | Valve | Gas valve stuck open. |

| E98 | Engineer | PCB | Internal control board error. |

| E99 | Engineer | PCB | Internal control board error. |

| A1 | Engineer | Pump | Pump seized or failing. |

| A3 | Engineer | Flue | Flue sensor detected blockage. |

| 47 | Engineer | Burner | Burner thermostat open. |

| Cl | Check | Remote | Remote control connection lost. |

Potterton

| Code | Type | Meaning | How to Fix / Action |

|---|---|---|---|

| E119 | DIY Fix | Low Pressure | Water pressure below 0.5 bar. |

| E133 | Check | No Gas | Condensate frozen or gas off. |

| E160 | Engineer | Fan | Fan not reaching set speed. |

| E110 | Engineer | Overheat | Safety thermostat operated. |

| E125 | Engineer | Circulation | Pump failure or air lock. |

| E168 | Engineer | PCB | Process error on PCB. |

| E20 | Engineer | NTC | Flow sensor fault. |

| E28 | Engineer | NTC | Flue sensor fault. |

| E50 | Engineer | DHW | Hot water sensor fault. |

| E193 | Engineer | Air | Air removal cycle running. |

| E151 | Engineer | PCB | Reset button pressed too often. |

| E152 | Engineer | PCB | Reset button stuck. |

| E153 | Engineer | Reset | Boiler locked out. Reset required. |

| E21 | Engineer | PCB | PCB manufacture fault. |

| E90 | Engineer | Wiring | Connection to PCB lost. |

Code Not Listed? Or Need a Repair?

Some faults are dangerous. We are Gas Safe Registered (555620).

Call 01942 466 486 NowWigan’s Trusted Boiler Repair & Heating Experts

Why Choose JJK Gas Services for Your Heating Needs?

At JJK Gas Services, we pride ourselves on delivering fast, affordable, and professional boiler repair and plumbing solutions throughout Wigan and the surrounding areas. Whether you're dealing with a frozen condensate pipe, low boiler pressure, or no heating or hot water, our Gas Safe registered engineers are just a call away.

Fast Response – Reliable Service – Local Experts

From boiler breakdowns to annual servicing and emergency plumbing, our team ensures you stay warm, safe, and energy-efficient all year round. We work with all major boiler brands and provide honest advice with no hidden fees.

Need Help With Your Boiler or Heating?

If you’re experiencing issues or have questions about your heating system, don’t hesitate to reach out. You can contact us via phone, email, our website, or social media. At JJK Gas Services, we’re always ready to help keep your home running efficiently and comfortably. call: 01942 466 486 or visit facebook for our messaging service or book a callback through the website at