Boiler Repairs Near Me: Expert Emergency Repair and Servicing Guide

Did you know that 90% of UK homes rely on a boiler for reliable heating and hot water? A sudden breakdown can leave families without warmth and disrupt daily routines, so knowing how to secure prompt, expert help for boiler repairs near me, including specialised boiler repair in Wigan, is essential. This guide reveals emergency repair options, common fault diagnoses and fixes, cost expectations for 2025, the importance of professional servicing, ways to find a trusted Gas Safe engineer, and a transparent repair process overview. By understanding each step—from urgent response times to restoring peak performance—you can restore comfort safely, minimise unexpected charges, and maintain peak boiler performance throughout colder seasons.

What Emergency Boiler Repair Services Are Available Near Me?

Emergency boiler repair services deliver rapid fault diagnosis, component replacement, and system testing to restore heating and hot water without delay. Our Gas Safe registered engineers, including those specialising in boiler repair in Wigan, arrive equipped with essential spares and diagnostic tools, ensuring safety standards are met and reliability is regained. This 24/7 rapid-response repair mechanism minimises downtime and prevents further damage by addressing leaks, pressure failures, or ignition faults on the spot. Securing expert emergency support reduces the risk of freeze-related pipe bursts and keeps homes warm when it matters most.

When Should You Call for Emergency Boiler Repairs?

A homeowner should call for emergency boiler repairs as soon as a complete loss of heating or hot water occurs, or if you notice uncontrolled leaks, unusual smells, or persistent pilot-light failures. Delaying professional intervention can lead to water damage, frozen condensate pipes, or safety hazards from combustible gas leaks. Immediate contact with a certified engineer prevents minor issues from escalating into costly system failures or dangerous carbon monoxide risks. Recognising these warning signs early ensures interruptions are minimised and heating reliability is quickly restored.

How Do Certified Gas Safe Engineers Handle Boiler Emergencies?

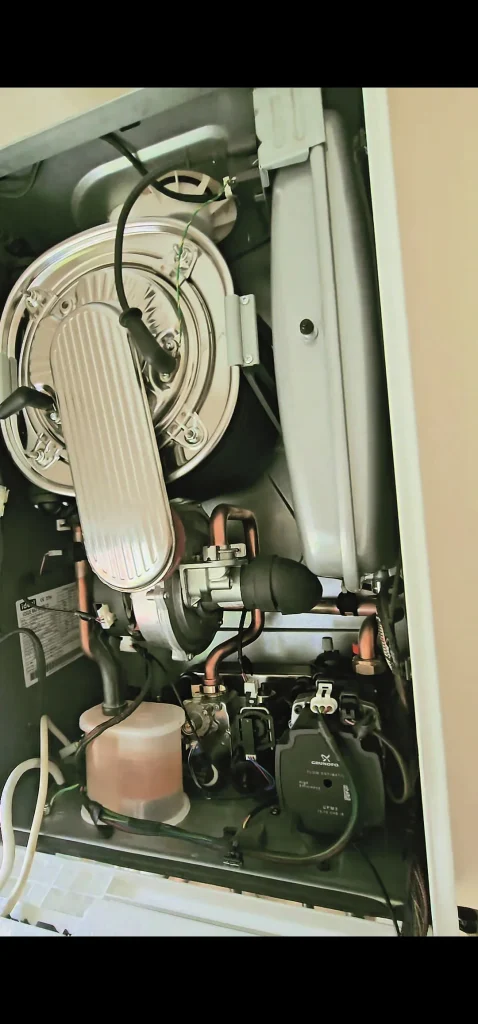

Certified Gas Safe engineers begin emergency calls by isolating the fuel supply and conducting a visual safety inspection of all visible pipework and fittings. They then perform electronic diagnostics on ignition systems, pressure controls, and safety valves to pinpoint the root cause of the failure. After identifying faulty parts—such as a damaged heat exchanger or defective pump—they replace or repair components using manufacturer-approved spares and recalibrate system parameters. A final pressure test and combustion analysis confirm the boiler operates safely and efficiently before the engineer leaves.

What Are Common Causes of Boiler Breakdowns Requiring Emergency Service?

Boiler breakdowns demanding emergency intervention often stem from condensate pipe blockages in freezing weather, sudden pressure drops, or electronic control failures. Corroded heat exchangers and worn seals can trigger leaks, while scaling inside heat exchangers reduces water flow and causes system shutdowns. Faulty ignition leads to repeated lockouts, leaving homes without heat or hot water until a professional resets and repairs the appliance. Recognising these frequent causes helps homeowners understand why urgent expert repairs preserve both safety and performance.

How Quickly Can Emergency Boiler Repairs Be Completed?

Most emergency boiler repairs near me can be completed within two to four hours, depending on spare part availability and scope of work. Simple fixes—like replacing a faulty valve or cleaning a condensate trap—often take under two hours, while more complex heat-exchanger replacements may extend to a half-day service. Our rapid-response engineers carry common parts to ensure most breakdowns are resolved in a single visit, minimising repeat call-outs and restoring heating promptly. Swift completion times reduce the risk of secondary damage and help maintain consistent home comfort.

What Are the Most Common Boiler Problems and How Are They Repaired?

Homeowners frequently encounter a range of boiler malfunctions that disrupt heating and hot water supply. The following list outlines the most common faults and their typical repair approaches.

- No heat or hot water due to failed ignition or thermostat faults.

- Water leaks from pipe joints, valves, or the heat exchanger.

- Low boiler pressure caused by escaping water or pump issues.

- Strange noises such as kettling, banging, or gurgling from scaling.

- Frozen condensate pipes blocking safe discharge.

How to Identify and Fix No Heat or Hot Water Issues?

No heat or hot water issues arise when ignition electrodes fail to spark or when the thermostat misreads temperature data. Engineers inspect the flame sensor, ignition leads, and gas valve operation to pinpoint the malfunction. Replacing worn ignition components or recalibrating the thermostat restores reliable burner operation, ensuring consistent heating demand is met. A clean combustion chamber and proper gas pressure settings further prevent recurring cold-water episodes.

What Causes Boiler Leaks and How Are They Repaired?

Boiler leaks often occur at corroded joints, degraded seals, or within the heat exchanger where metal fatigue develops over years of thermal cycling. Technicians locate the source by pressure-testing the system and visually inspecting pipework and connections. Leaking valves or seals are replaced with high-grade components, while damaged sections of copper or stainless-steel pipework are cut out and refitted. Following repair, the system is re-pressurised and monitored to confirm a watertight seal.

How to Resolve Low Boiler Pressure Problems?

Low boiler pressure typically results from escaping water through minor leaks or a failing expansion vessel that cannot compensate for temperature fluctuations. Service engineers first verify the expansion vessel pre-charge and refill the system to the recommended 1.0–1.5 bar range. They then inspect for slow leaks at radiators, pipe joints, and the pressure relief valve. Correcting the pre-charge and eliminating leaks restores stable system pressure, preventing freeze shutdowns and ensuring efficient heat transfer.

What Do Strange Boiler Noises Indicate and How Are They Fixed?

Kettling sounds signal scale buildup inside the heat exchanger that restricts water flow and overheats the metal, while banging noises indicate air trapped in the system or a failing pump. Engineers flush out limescale deposits with a power-flush treatment or replace the heat exchanger if erosion is severe. Air bleed valves and vent traps clear trapped air pockets, restoring smooth circulation and eliminating disruptive noise. Completing these repairs enhances combustion efficiency and extends boiler lifespan.

How to Fix Frozen Condensate Pipes Safely?

Frozen condensate pipes block flue-gas drainage, triggering boiler lockouts to prevent dangerous flue-gas accumulation. Safe thawing methods include applying warm water or a heated blanket around the pipe while wearing protective gloves. Engineers may also insulate vulnerable condensate lines with foam jackets or reroute sections to avoid frost exposure. Clearing the blockage and improving pipe protection prevents recurring freeze events and maintains continuous boiler operation.

How Much Does Boiler Repair and Servicing Cost Near Me?

Understanding boiler repair and servicing costs near me helps homeowners budget effectively and avoid unexpected charges. The table below summarises average repair, service, and call-out fees for 2025 within the UK market.

| Repair Type | Average Cost (£) | Call-Out Fee (£) |

|---|---|---|

| Standard boiler repair | 150–600 | 100–150 |

| Emergency boiler repair | 300–500 | 120–150 |

| Annual boiler service | 75–125 | 100–120 |

| Heat exchanger replacement | 400–1,000 | 120–150 |

These ranges reflect parts, labour, and regional variations. Transparent pricing ensures homeowners know what to expect before work begins and minimises the risk of concealed charges.

What Is the Average Cost of Boiler Repairs in 2025?

The average cost of boiler repairs in 2025 ranges between £150 and £600, depending on the complexity of the issue and parts required. Routine fixes—such as replacing a faulty valve or thermistor—tend toward the lower end, while significant component replacements, like heat exchanger or circuit board swaps, can approach the upper bracket. Engineers provide upfront quotes based on diagnostic findings to maintain transparent pricing.

UK Combination Boiler Performance and Replacement Costs

Space heating operation of combination boilers in the UK: The case for addressing real-world boiler performance. Performance gap issues in gas boiler cost through the ongoing replacement of millions of boilers. Space heating operation of combination boilers in the UK: The case for addressing real-world boiler performance, G Bennett, 2019

How Much Does an Annual Boiler Service Typically Cost?

A standard annual boiler service typically costs between £75 and £125, covering a thorough inspection, cleaning of burner and heat-exchanger components, safety checks on pressure relief valves, and performance calibration. This preventative maintenance preserves efficiency, extends warranty compliance, and reduces the likelihood of emergency breakdowns.

What Are Call-Out Fees and Emergency Repair Charges?

Call-out fees for non-emergency visits generally range from £100 to £120, while emergency boiler repair charges—including weekend or out-of-hours responses—can add £20 to £30 to the base call-out cost. These fees cover travel, diagnostics, and priority status to ensure rapid engineer deployment.

When Is It More Cost-Effective to Replace Rather Than Repair a Boiler?

Replacing a boiler becomes more cost-effective when repair costs exceed 50% of a new unit’s price or when the appliance is over 10–15 years old with frequent breakdowns. Investing in a new energy-efficient model reduces long-term running costs, offers warranties up to 10 years, and supports current government decarbonisation initiatives for low-carbon heating.

Life-Cycle Cost Analysis of Energy-Efficient Furnaces and Boilers

This paper presents the estimated change in LCC associated with more energy-efficient equipment. US residential furnace and boiler energy-efficiency standards. Determining cost-effectiveness Life-cycle cost analysis of energy efficiency design options for residential furnaces and boilers, 2006

What Does a Professional Boiler Service Include and Why Is It Important?

A professional boiler service provides comprehensive preventative maintenance to ensure safe, efficient, and warranty-compliant operation. Technicians perform flue integrity checks, clean critical combustion components, test safety controls, and verify system pressure and heat exchange efficiency. This thorough inspection mechanism identifies early-stage faults, prevents performance degradation, and extends boiler longevity by addressing wear before it escalates into costly repairs.

What Are the Benefits of Annual Boiler Servicing?

Annual boiler servicing enhances energy efficiency by maintaining clean heat-exchanger surfaces and optimal burner performance, which can save up to 10% on fuel bills. Regular safety valve and flue checks ensure compliance with Gas Safe standards, reducing carbon monoxide risks. Maintaining manufacturer-approved service intervals also preserves warranty coverage, protecting homeowners from unexpected component failures.

What Is Included in a Boiler Maintenance Checklist?

The maintenance checklist below outlines essential tasks that maintain boiler reliability and safety.

| Maintenance Task | Purpose | Frequency |

|---|---|---|

| Flue and chimney inspection | Verify safe exhaust of combustion gases | Once per service |

| Burner and heat-exchanger clean | Remove deposits for efficient combustion | Once per service |

| Pressure relief valve test | Confirm proper operation under pressure | Once per service |

| Expansion vessel check | Ensure correct system pressure control | Once per service |

| Electrical component inspection | Detect wiring faults or sensor failures | Once per service |

How Does Regular Servicing Prevent Boiler Breakdowns?

Regular servicing prevents breakdowns by detecting minor corrosion, seal degradation, and scaling early, before they impair heat transfer or system integrity. Correcting these issues during scheduled visits avoids unplanned shutdowns, emergency call-out fees, and water damage from leaks. Consistent maintenance also ensures combustion efficiency remains high, reducing fuel consumption and environmental impact.

How Can I Find a Trusted Heating Engineer Near Me for Boiler Repairs?

Finding a trusted heating engineer involves verifying Gas Safe registration, local experience, and transparent pricing practices. Gas Safe registration confirms adherence to UK safety regulations for gas-appliance work, ensuring repairs meet legal and safety standards. Local engineers often provide faster response times, understand regional water quality issues, and maintain community reputations through word-of-mouth referrals, making it easier to find reliable boiler repair in Wigan.

Why Is Hiring a Gas Safe Registered Engineer Essential?

Hiring a Gas Safe registered engineer is essential because they have undergone rigorous assessments in gas safety, flue testing, and appliance competence. Registration guarantees that work on boilers complies with legal requirements and safety protocols, reducing carbon monoxide risks and ensuring valid warranty activation.

How to Verify Local Engineer Qualifications and Experience?

To verify qualifications, request the engineer’s Gas Safe registration number and cross-check it on the official register. Ask for proof of public liability insurance and examples of recent boiler repairs in your area. Local references and online reviews further confirm track record and customer satisfaction.

What Are the Advantages of Choosing a Local Boiler Repair Service?

Choosing a local boiler repair service delivers faster emergency response, familiarity with common regional boiler models, and streamlined communication. Local engineers invest in community reputation and often offer transparent, fixed-price quotes without hidden fees. Their proximity also reduces travel time and call-out costs.

What Are the Steps in the Boiler Repair Process Near Me?

The boiler repair process near me follows a clear five-step journey—diagnosis, quotation, repair, testing, and certification—to ensure transparency and trusted outcomes. This structured workflow guides homeowners through each phase, clarifies costs, and confirms compliance with safety standards before completion.

How Is a Boiler Diagnosed and Faults Identified?

Diagnosis begins with isolating the appliance and conducting a full system pressure check, followed by electronic testing of ignition and control components. Engineers inspect gas valves, flame sensors, and heat-exchanger condition using diagnostic meters. Pinpointing the exact fault establishes a repair plan that minimises unnecessary part replacements.

What Happens During the Repair and Testing Stages?

During repair, defective components are replaced or serviced—ranging from seals and valves to pumps and circuit boards. After reinstalling parts, engineers perform pressure tests, combustion analyses, and safety valve checks to verify correct operation. Confirming stable pressure and proper flue gas composition ensures the system meets efficiency and safety requirements.

How Are Repairs Quoted and What Does Transparent Pricing Look Like?

Engineers provide written quotations that list labour hours, part costs, call-out fees, and any additional charges—such as out-of-hours surcharges—for full price transparency. Itemising each charge prevents unexpected bills and fosters trust by ensuring homeowners approve work before it begins.

What Certification or Guarantees Are Provided After Repair?

After completing repairs, engineers supply a Gas Safe compliance certificate and a parts warranty covering replaced components for 12 months. These guarantees protect homeowners against premature failures and confirm that work adheres to statutory safety regulations.

Contact a Gas Safe registered engineer today to arrange emergency repairs or schedule your next service, and enjoy reliable heating with no hidden costs. For expert boiler repair in Wigan, trust our certified professionals. Call us on 01942 466486 or visit our website at www.jjkgasservices.co.uk.

Wrote by JJK Gas Services, proofed by Stephen Knight, Lead Engineer.