What Are the Different Types of Radiators to Install in My Home?

Home radiators are the heat-delivery devices that transfer thermal energy from a boiler or electric element into living spaces, and choosing the right type affects comfort, energy use, and interior design. This guide explains radiator types, materials, heating mechanisms, sizing by BTU, installation costs, thermostatic radiator valves (TRVs), and long-term maintenance so you can make an informed decision for each room. Many homeowners struggle with mismatched heat output, bulky styles, or inefficient controls; this article fixes that by mapping radiator styles (panel, column, towel, designer, vertical/horizontal) to typical room uses and performance trade-offs. You will learn how materials like steel, aluminium, cast iron, and stainless steel change heat-up time and durability, how to calculate required BTU with worked examples, and what installation and maintenance steps matter most. The article also covers central vs electric vs dual-fuel options, TRV choices (mechanical vs smart) and practical flushing and bleeding procedures for system longevity. Read on for EAV comparison tables, step-by-step BTU calculations, installer vetting checklists, and actionable maintenance steps to keep your heating efficient and reliable.

What Are the Main Types of Home Radiators?

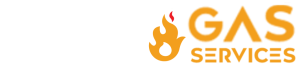

Panel, column, towel, designer, and vertical/horizontal radiators each deliver heat through convection and radiation and suit different rooms and design goals. Panel radiators use flat panels with optional convector fins to increase surface area and convection; column radiators use connected tubular columns that store and slowly release heat; towel radiators are rails designed for bathrooms with moisture considerations; designer radiators prioritize aesthetic form with varying performance; vertical and horizontal layouts adapt to space constraints and heat-distribution needs. Each type balances heat output, visual impact, and installation complexity, so matching room function to radiator characteristics improves comfort and efficiency. Below is a compact comparison to guide selection by room use, pros/cons, and aesthetic notes.

| Radiator Type | Typical Room Use | Key Pros / Cons |

|---|---|---|

| Panel Radiators (Type 11/21/22/33) | Living rooms, bedrooms, kitchens | High convective output, compact, widely available; convector fins increase heat but add bulk |

| Column Radiators | Period properties, large rooms | Strong heat retention, decorative; heavy and slower to respond |

| Towel Radiators | Bathrooms and en-suites | Dual-purpose drying and heating; requires correct IP rating and safe electrical setup |

| Designer Radiators | Halls, living spaces, feature walls | Statement pieces with varied finishes; usually costlier for same BTU |

| Vertical Radiators | Narrow walls, modern layouts | Space-saving and tall; may require more BTU per linear metre for same perceived warmth |

This table clarifies where each radiator type performs best and what trade-offs to expect when designing room-level heating and aesthetics.

What Defines Panel Radiators and Their Common Configurations?

Panel radiators are flat steel panels with optional convector fins; they deliver heat mainly through convection aided by fins that increase surface area. The Type numbering (Type 11, 21, 22, 33) indicates the number of panels and convector layers: Type 11 is single panel single convector, Type 21 is double panel single convector (often called P1), Type 22 is double panel double convector (K2), and Type 33 is triple panel triple convector. This construction drives BTU output: more panels/convector layers increase heat output per length, so a Type 22 will typically produce substantially more BTU than a Type 11 of the same length. Choose Type 11 for small bedrooms or corridors where low output suffices, Type 21 for standard rooms, and Type 22/33 for larger or poorly insulated spaces where higher output is needed.

Panel radiators work well with modern boilers and TRVs because their convective surface quickly responds to flow temperature changes, and the next section explains how column radiators contrast in retention and style.

How Do Column Radiators Differ in Style and Heat Retention?

Column radiators consist of vertical tubular sections joined horizontally; their components—individual columns and header connections—create thermal mass that stores heat and releases it slowly. Cast iron or steel column radiators deliver longer heat retention compared with thin-panel designs, so they are ideal where sustained, gentle warmth is preferred, such as in period living rooms or bedrooms with intermittent heating. The visual language of column radiators suits heritage interiors and provides a tactile focal point, but the trade-offs include substantial weight, need for robust wall fixings or floor mounts, and generally slower response time to thermostat changes.

If you want lingering warmth after the boiler cycles off, column radiators provide that benefit, and the following subsection covers towel radiators specifically for bathroom environments.

What Are Towel Radiators and Their Uses in Bathrooms?

Towel radiators (rail-type) are designed to combine room heating with towel warming and typically come in central-heating, electric, or dual-fuel variants to meet seasonal needs. Their mechanism uses multiple horizontal rails heated by hot water or an electric element; the result is convective airflow in the bathroom plus radiant warmth for textiles. Choose towel radiators with an appropriate IP rating for bathrooms and ensure fixings and valves are rated for humid environments; if electric elements are used, an isolation switch and correct wiring are mandatory for safety. Positioning is important—mount at a height that dries towels effectively without blocking heat circulation—and the next section contrasts designer radiators and their aesthetic advantages.

What Are Designer Radiators and Their Aesthetic Advantages?

Designer radiators prioritize visual design while still functioning as heating elements; they come in flat panels, geometric shapes, or sculptural forms and often use premium finishes like brushed stainless or powder-coat colours. The mechanism remains heat transfer via convection and radiation, but manufacturers balance form with surface area to deliver required BTU; as a result, designer units can be costlier per BTU than standard panels. Use designer radiators where visual impact matters—entrances, living rooms, and feature walls—and accept that compromise between appearance and maximal thermal efficiency may require slightly larger or higher-output models. After considering aesthetics, vertical versus horizontal layouts influence placement and perceived warmth, which we address next.

How Do Horizontal and Vertical Radiators Compare for Space and Design?

Horizontal radiators are the traditional under-window placement that combats cold downdrafts and spreads heat evenly across lower wall area, while vertical radiators free up horizontal wall space and suit narrow alcoves or contemporary styles. Heat distribution depends on surface area and placement: horizontal units under windows counteract glazing heat loss, whereas vertical units may need increased output per linear metre to achieve the same perceived warmth. Vertical radiators can act as statement pieces and often pair well with tall ceilings, but they may concentrate heat higher on the wall which alters convection patterns. Consider room layout—furniture positioning, window size, and ceiling height—when choosing orientation to balance comfort and interior design.

How Do Radiator Materials Affect Performance and Durability?

Radiator material determines thermal conductivity, weight, corrosion resistance, and installation considerations, so material choice directly affects heat-up time, heat retention, and lifecycle costs. Steel, aluminium, cast iron, and stainless steel each offer different trade-offs: steel is cost-effective and common in panel radiators; aluminium heats quickly and cools rapidly; cast iron retains heat long after the boiler stops; stainless steel provides corrosion resistance in coastal areas. Below is a concise material comparison to help select the right balance of performance and durability for your system and local conditions.

| Material | Thermal Conductivity / Weight | Durability / Corrosion | Typical Cost |

|---|---|---|---|

| Steel | Moderate conductivity, medium weight | Good but susceptible to corrosion without inhibitor | Low to mid |

| Aluminium | High conductivity, light weight | Corrodes less when properly finished; sensitive to aggressive inhibitors | Mid |

| Cast Iron | Low conductivity, very heavy | Exceptional longevity and heat retention; resistant when painted | High |

| Stainless Steel | Moderate-high conductivity, heavier than aluminium | Excellent corrosion resistance, ideal for coastal areas | High |

This material table clarifies how conductivity and longevity trade off against cost and weight, guiding material selection for both performance and lifespan.

What Are the Benefits of Steel Radiators for Home Heating?

Steel radiators offer a practical balance of upfront cost, performance, and availability, and they form the backbone of most panel radiator ranges used in modern homes. Mechanically, steel panels with convector fins create efficient convective heat transfer and respond reasonably quickly to flow temperature changes, making them compatible with modulating boilers and TRVs. Steel is widely available in standard sizes, which simplifies replacement or matching across rooms, but steel can corrode if the central heating system lacks proper inhibitor or has aggressive water chemistry. Given these attributes, steel is a solid default for cost-conscious installations in contemporary homes.

How Do Aluminium Radiators Provide Quick Heat Output?

Aluminium radiators have high thermal conductivity and low mass, so they reach operating temperature quickly and provide fast zonal control when heating is needed on demand. This quick response makes aluminium suitable for rooms that require rapid warm-up, such as bathrooms or intermittently used guest rooms, and aluminium’s light weight simplifies handling and mounting. The trade-offs include a tendency to cost more than basic steel panels and the need for compatible corrosion inhibitors and system chemistry to avoid accelerated corrosion. Use aluminium where speed of response and lightweight fitting are priorities, and the next subsection explores the opposite characteristic—cast iron’s heat retention.

Why Choose Cast Iron Radiators for Heat Retention?

Cast iron radiators have high thermal mass and store heat effectively, releasing warmth gradually even after the boiler stops, which suits homes where long, slow heat is desirable. The mechanism—massive iron sections heated by circulating water—means less frequent boiler cycling and a steady ambient temperature, particularly helpful in poorly insulated older properties. Cast iron is heavy and requires sturdy fixings or floor-mounted supports and can be costlier to purchase and install, but its longevity and classic aesthetic often justify the investment in period property restorations. Where slow-release warmth and traditional appearance matter, cast iron remains a compelling choice.

How Does Stainless Steel Compare in Durability and Style?

Stainless steel radiators combine a modern aesthetic with high corrosion resistance, making them particularly good for humid or coastal locations where salt and moisture accelerate corrosion in other metals. Their thermal performance sits between steel and aluminium, and premium finishes provide strong design flexibility for interiors seeking sleek, contemporary looks. The primary downsides are higher cost and fewer standard sizes compared with mild steel panels, which can complicate matching across a whole-house replacement. Choose stainless steel when corrosion resistance and finish are priority decision factors, and weigh costs against long-term durability benefits.

What Are the Cost Differences Between Radiator Materials?

Material choice influences not only purchase price but installation complexity and lifecycle costs, so evaluate total cost of ownership rather than upfront price alone. Generally, mild steel panels are the most economical, aluminium sits at mid-range due to manufacturing costs and performance benefits, while cast iron and stainless steel are at the higher end because of material expense and weight-handling requirements. Consider lifecycle factors such as potential energy savings from improved efficiency, the need for stronger fixings or plumbing work for heavy units, and maintenance costs related to corrosion protection and inhibitors. Balancing these cost elements against room-specific requirements yields an optimal material decision.

What Are the Different Radiator Heating Mechanisms?

Radiators operate via several mechanisms—central heating (water-based), electric, and dual fuel—each with different installation paths, control options, and energy implications. Central heating radiators connect to a boiler and circulate hot water through a flow and return; electric radiators heat via internal elements and offer room-level independence; dual fuel combines central heating with an electric element for offseason use or zonal flexibility. System efficiency depends on the heat source, controls like TRVs, and building insulation; choose the mechanism that aligns with whole-home strategy and local energy costs. Below are practical pros and cons to compare mechanisms for typical home scenarios.

- The following lists outline pros and cons of each mechanism.

- Each list highlights core advantages and typical limitations for homeowner decision-making.

- Use these lists to match mechanism to use-case before comparing running costs and installation complexity.

- Central heating radiators offer whole-house integration, efficient distribution with modern boilers, and compatibility with TRVs; they require pipework and periodic flushing.

- Electric radiators provide simple installation and per-room control but can have higher operational costs depending on electricity prices.

- Dual fuel radiators combine the convenience of electric operation with central-heating integration for flexible seasonal use and can be economical for partial-home heating.

These comparisons show that mechanism choice depends on whether you prioritize installation simplicity, running cost, or zoning flexibility; next we examine central heating operation details.

How Do Central Heating Radiators Work and When Are They Ideal?

Central heating radiators receive hot water from a central boiler via a flow and return loop; the circulating pump moves heated water through radiator panels where thermal energy transfers to room air and surfaces. This mechanism is ideal for whole-house systems where a single efficient heat source supplies multiple zones controlled by thermostats and TRVs, producing consistent distribution and centralised maintenance. Central systems require periodic flushing and inhibitor use to prevent sludge and corrosion that reduce heat transfer and strain pumps, and installers must size pipework for balanced flow. For homes aiming for integrated zoning and smart-control compatibility, central heating radiators remain the standard approach.

What Are Electric Radiators and Their Pros and Cons?

Electric radiators use internal heating elements—often with thermostatic control and sometimes with oil-filled thermal stores—to provide direct heat without boiler connection, enabling simple retrofits in rooms not on the central system. Pros include straightforward installation, precise room-level control, and no need for pipework; cons include potentially higher running costs depending on electricity rates and the absence of central-system efficiencies like condensing boiler performance. Electric radiators are well-suited to extensions, loft conversions, or rooms used intermittently, and they pair well with smart controls to optimise schedules. When choosing electric options, consider element type, thermal store capacity, and integration with home energy management.

How Do Dual Fuel Radiators Combine Central Heating and Electric Power?

Dual fuel radiators, commonly used for towel rails, contain a central-heating connection plus an electric element that can operate independently during warmer months or when the central system is off. The switching mechanism requires either a manual isolation switch or a built-in thermostat and must meet wiring regulations; this hybrid setup gives year-round convenience without rerouting pipework. Dual fuel is ideal in bathrooms or partial-use rooms where you want drying or quick warmth outside the boiler season, and installers often advise isolating the electric element when on central heating to avoid simultaneous energy use. Properly specified, dual fuel offers flexible control and reduced energy waste for targeted zones.

Which Heating Mechanism Is Most Energy Efficient?

Energy efficiency depends more on the primary heat source, control strategy, and building fabric than on radiator type alone; a well-controlled central system with a modern condensing boiler or heat pump plus TRVs and zoning can outperform independent electric units in whole-home scenarios. Key relationships: boiler efficiency → determines system COP and fuel-to-heat conversion; TRV + thermostat coordination → reduces wasted heat by zoning; insulation and airtightness → reduce required BTU overall. For spot heating, electric radiators with smart scheduling may be efficient if used only when needed, but across a whole house the choice of heat source (e.g., heat pump vs gas boiler) and controls tends to dominate energy outcomes. Evaluate mechanism within the broader system context to determine real-world efficiency.

How Do I Choose the Right Radiator Size and Heat Output for My Home?

Selecting radiator size requires calculating the room’s heat requirement in BTU (or watts), accounting for room volume, insulation, glazing, and desired internal temperature; then select a radiator whose rated output meets or slightly exceeds that requirement. BTU (British Thermal Unit) measures heat energy needed to raise one pound of water by 1°F; manufacturers often give radiator outputs in BTU or watts at standard Delta-T conditions. Use a stepwise approach: measure room, apply modifiers for external walls and insulation, compute required BTU, then choose radiator type and length that provides that output—Type 22 will deliver more BTU per metre than Type 11.

| Radiator Type / Size | Example Dimension | Typical BTU Output (approx) |

|---|---|---|

| Type 11 – 600 x 600 mm | Small panel | 2,000–2,500 BTU |

| Type 21 – 600 x 1000 mm | Standard double panel | 4,000–5,000 BTU |

| Type 22 – 600 x 1200 mm | Double panel double convector | 6,000–8,000 BTU |

| Column – 600 x 1200 mm | 6-column | 3,500–6,000 BTU |

Use these example outputs as guidance only; always confirm with manufacturer data and adjust for room-specific factors described below.

What Is BTU and Why Is It Important for Radiator Sizing?

BTU is an energy unit indicating how much heat is delivered; one watt equals 3.412 BTU, so conversion is BTU = Watts × 3.412, which helps translate manufacturer watt ratings to BTU targets. Understanding BTU matters because radiator selection must match room heat loss—undersized radiators fail to maintain temperature, while oversized radiators waste space and cost more to run. For example, a room requiring 5,000 BTU needs a radiator (or combination) with at least that output at the expected flow/return temperatures. This numeric clarity guides whether to pick Type 21, Type 22, or a larger column unit to meet heating needs.

How Do Room Size and Insulation Affect Radiator Requirements?

Room heat loss scales with volume and with the thermal performance of walls, windows, and ceilings; poorly insulated rooms or rooms with large single-glazed windows or external walls require higher BTU margins. Simple rules of thumb adjust the base BTU by multipliers: add 10–20% for rooms with external walls or south-facing glazing, add 20–30% for poorly insulated loft conversions or high ceilings, and reduce 10–20% for well-insulated, modern homes. These adjustments ensure the radiator compensates for real heat loss rather than idealised conditions; next we give a step-by-step calculation method.

How Can I Calculate the Correct Radiator Size Step-by-Step?

Follow a reproducible sequence: measure room length × width × height to get volume; estimate base BTU per cubic metre (or use per-square-metre rule) then apply modifiers for insulation, glazing, and orientation; convert to radiator output units (watts or BTU) and select a radiator whose rated output meets or slightly exceeds the target. For example, a 4m × 3m × 2.4m bedroom (28.8 m3) might need ~40–50 W/m3 depending on insulation—calculate total watts, convert to BTU, then choose a radiator type/length with that rating. When in doubt, select a slightly higher output radiator and control via TRVs to avoid overheating.

What Are Typical BTU Outputs for Common Radiator Types?

Manufacturer outputs vary, but general patterns hold: Type 11 yields the least BTU per length, Type 21 moderate, Type 22 substantially higher, and Type 33 highest for standard depths; material and convector count also change outputs. Use the sample table above as a starting guide and note that aluminium units often rate higher BTU for the same size due to higher conductivity. Always verify with manufacturer BTU/watt tables at the specified Delta-T and account for system flow temperature when finalising radiator selection.

What Are the Costs and Considerations for Radiator Installation?

Installing radiators involves material costs (radiator unit, valves, mounting), labor, and potential extras like pipe relocation, TRVs, system flushing, and disposal; these components determine the total quote and regional variation affects labor rates. Typical cost drivers include accessibility (wall removal or difficult access increases labor), pipework complexity (routing through floors or behind plaster), and system health (flushing or adding inhibitor may be required). Below is a practical cost breakdown and guidance on DIY versus professional choices to help you prepare and budget accurately for installation.

Installation cost components are listed to clarify what a quote should include. Use this list to compare installer quotes and identify items that may be excluded or added later. After the list, read the vetting checklist to ensure installer competence and clear pricing.

- Radiator unit cost: varies by type and material.

- Valves and TRVs: usually extra per radiator and necessary for zoning.

- Labor: chargeable by time or per-radiator rate; accessibility affects time.

- Additional pipework, moving pipe runs, or partial wall work: add to labor and materials.

How Much Does It Cost to Install Different Types of Radiators?

Costs vary by radiator type and installation complexity; standard steel panel replacements are generally the least expensive to fit, while heavy cast iron or bespoke designer radiators raise both material and labor costs. Extras such as fitting TRVs, moving pipework, or performing a system flush add to the total; expect variability by region and by whether structural changes are needed. Always request a breakdown showing unit price, valve costs, labor hours, materials, and any system service like flushing or inhibitor addition to compare like-for-like quotes. Getting multiple estimates reveals the range and highlights potential hidden costs before work begins.

Should I Choose DIY or Professional Radiator Installation?

Simple swaps where pipework and valves remain unchanged may be suitable for skilled DIYers with plumbing experience; however, jobs involving new pipe runs, moving radiators, or altering boiler connections are best handled by qualified professionals. Safety, warranty implications, and regulatory requirements (for gas boiler changes and electrical elements) demand professional involvement in many cases. If you have the necessary tools, confidence in pipework soldering or compression fittings, and can isolate and drain the system safely, DIY can save money; otherwise hire a professional to avoid leaks, pressure issues, or voiding warranties.

What Factors Influence Radiator Installation Prices?

Several variables change the final quote: radiator type and material, location accessibility, need to move or rework pipework, inclusion of TRVs and valve sets, requirement for system flushing or inhibitor addition, and regional labor rates. For example, replacing a radiator in an upstairs bedroom may be cheaper than moving pipework through a tiled bathroom or adapting cast iron fixings. Transparency in quotes—detailing labor hours, parts, and system services—lets you compare value across estimates. The following checklist helps vet installers and request specific quote items.

Before work starts, obtain at least three written quotes and vet installers using this checklist:

- Request itemised pricing: parts, labor, valves, and flushing.

- Ask for evidence of insurance and relevant qualifications.

- Confirm whether warranty and post-installation testing are included.

This vetting reduces the risk of surprise costs and ensures installers will include essential services such as flushing and TRV installation.

What Are Thermostatic Radiator Valves and How Do They Improve Efficiency?

Thermostatic radiator valves (TRVs) are temperature-sensing valves fitted to radiators that modulate hot-water flow based on local room temperature, providing zoning and preventing overheating. TRVs contain a sensor element that expands or contracts with temperature changes, actuating the valve body to throttle water flow and thus maintaining a setpoint without central thermostat intervention. Benefits include energy savings through targeted heating, improved comfort by avoiding overheating in unused rooms, and better boiler cycling when combined with correct system controls. Below we compare TRV types and explain optimal installation and use.

How Do TRVs Work to Control Room Temperature?

A TRV senses room air temperature via a wax/liquid or electronic sensor and adjusts the valve opening to regulate hot-water flow through the radiator, so the radiator’s local output matches the set temperature. This mechanism enables zoning: rooms with lower setpoints receive less flow while occupied rooms maintain comfort, reducing wasted heat and improving overall system efficiency. TRVs differ from the central thermostat because they control local radiators independently; common issues include incorrect placement (e.g., behind curtains) or stuck valves due to infrequent use, which require troubleshooting or replacement. Proper positioning and occasional operation ensure reliable TRV performance and longevity.

What Are the Energy-Saving Benefits of Installing TRVs?

TRVs save energy by enabling room-level control and preventing overheating in unoccupied spaces, which reduces fuel consumption and can lower bills when used with sensible schedules and a primary thermostat. Studies and practical experience indicate that zoning with TRVs often yields noticeable savings—commonly estimated in the range of 10–25% depending on building fabric, occupancy patterns, and control strategy. Best practices include not fitting TRVs to the same room as the central thermostat, setting slightly lower temperatures in rarely used rooms, and combining TRVs with a well-tuned central thermostat to avoid conflicting controls. When used correctly, TRVs reduce wasted heat and increase occupant comfort.

What Types of TRVs Are Available, Including Smart TRVs?

TRV options include mechanical wax/liquid TRVs (simple and robust), electronic TRVs with digital setpoints, and smart TRVs that integrate with home networks for scheduling and remote control; each type offers different precision, cost, and integration capabilities. Mechanical TRVs are inexpensive and durable, electronic TRVs add finer control and display, and smart TRVs provide app-based scheduling and analytics that further improve zoning and efficiency. Compare types by cost, control precision, integration needs, and battery or power requirements, and consult a heating professional to verify compatibility with your boiler and system layout before purchase.

How Should I Install and Use TRVs for Optimal Performance?

Install TRVs on every radiator except the one in the same room as the main thermostat, ensure they have clear airflow (not behind curtains or furniture), and set sensible seasonal setpoints to maximise savings. Use a short checklist for installation: isolate and drain system section, replace valve tails if corroded, fit TRV and check for leaks, then fully commission with proper balancing. Seasonal use: program lower setpoints in unused rooms and avoid fully closing TRVs if system needs minimum flow for boiler protection. Regular testing and occasional cycling of the head prevent sticking and maintain responsiveness.

What Is the Step-by-Step Process to Flush Radiators Safely?

A safe radiator flush sequence involves: isolating and draining the system section, removing the radiator if required or using a hose to flush from inlet to outlet until water runs clear, refitting and repressurising the system, and adding inhibitor per manufacturer recommendations. Time estimates: a single radiator flush can take 30–90 minutes for DIY, while professional power-flushing of a full system typically takes several hours. Essential safety notes: protect flooring, avoid contact with contaminated water, and shut down electrical components as needed; call a professional if you lack tools or the system shows severe sludge or corrosion.

How Do I Bleed Radiators to Remove Air and Improve Heat?

Bleeding removes trapped air that prevents hot water from filling the radiator, restoring even heat distribution and improving comfort; symptoms include cold tops and warm bottoms or gurgling noises. Use a radiator key to open the bleed valve slightly until water appears, then close securely and check boiler pressure—top up if needed. For safety and system stability, bleed radiators while the system is cool enough to avoid scalding and follow manufacturer guidelines to maintain correct system pressure. Regular bleeding as part of seasonal maintenance prevents minor issues from becoming major efficiency losses.

What Tools and Products Are Needed for Radiator Maintenance?

Essential tools include a radiator key, adjustable wrench, drain hose or bucket for flushing, and protective gloves; products include central-heating inhibitor, radiator cleaner for sludge removal, and compatible replacement valves or TRV heads. When choosing chemicals, select cleaners and inhibitors suitable for your system material (e.g., aluminium-compatible inhibitors if aluminium radiators are present) and follow disposal guidance for flushed water. Sources for parts and supplies include recognised retailers and installer channels—consider suppliers such as Screwfix or B&Q for parts, and comparison sites or services like MyBuilder or HomeServe to find qualified installers.

When preparing for installer consultation or a professional service, bring the following documents and questions:

- A list of room measurements and desired temperatures.

- Current system details (boiler type, flow/return temperatures if known).

- Photos of radiator locations and pipework to show accessibility.

This targeted preparation helps installers provide accurate BTU calculations, detailed quotes, and appropriate recommendations for flushing or TRV integration, and contacting a qualified heating professional is advisable for final sizing and installation decisions.